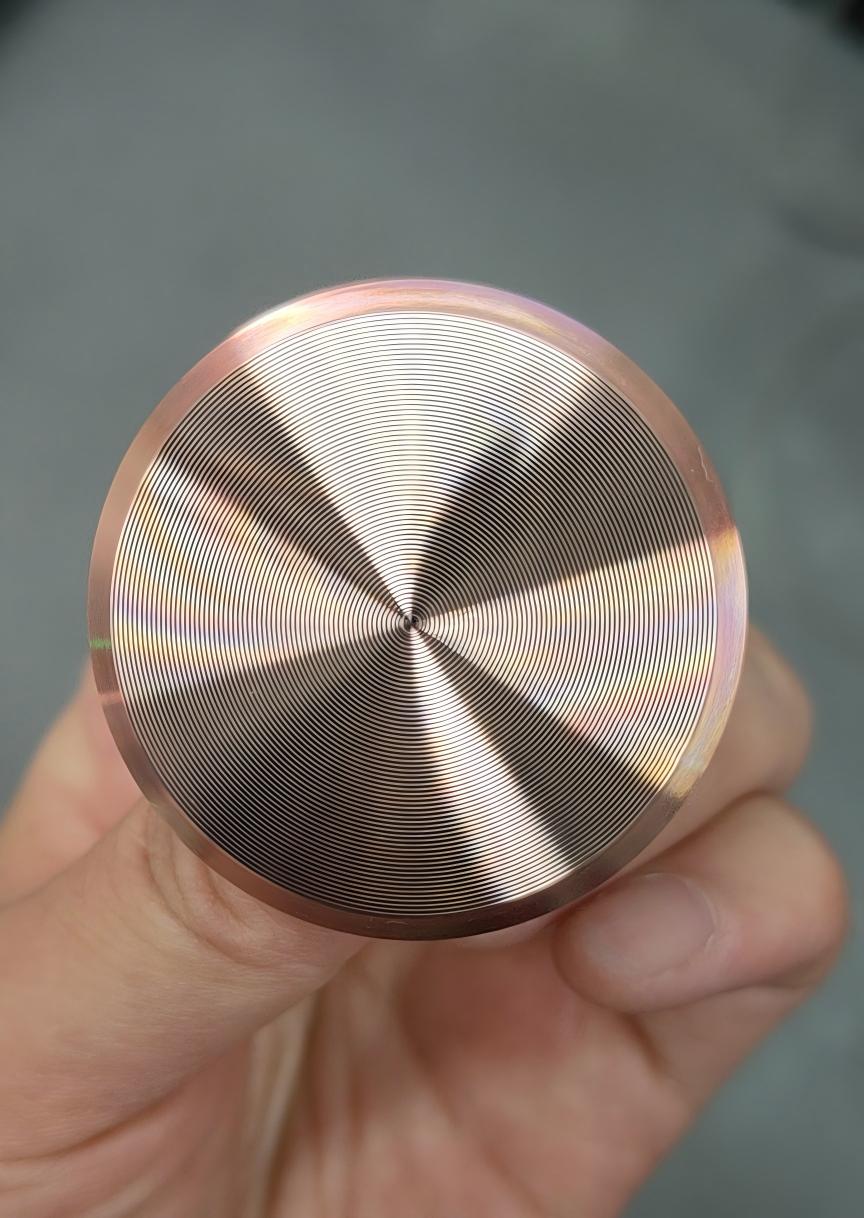

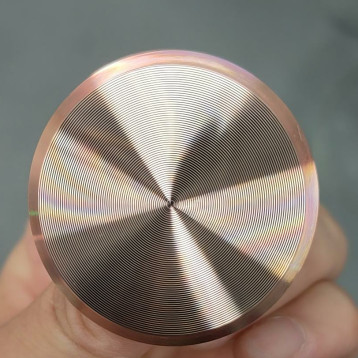

This high-precision CNC-turned helm screw features a custom CD (cross-diagonal) knurling pattern, designed for optimal grip and torque transmission in demanding applications. Ideal for marine, automotive, and industrial use, this screw combines durability with an ergonomic knurled surface for easy manual adjustment even in wet or oily conditions.

Key Features:

? CD Knurling (Diamond Pattern) – Enhanced multidirectional grip for secure handling.

? CNC Turning & Threading – Precision-machined threads for perfect fit and consistent performance.

? High-Strength Materials – Available in stainless steel (304/316), brass, or aluminum for corrosion resistance.

? Customizable Design – Adjustable knurl depth, pitch, thread size, and head style.

? Smooth, Burr-Free Finish – Rolled knurling ensures durability without sharp edges.

Common Applications:

• Marine & Boating – Helm control screws, throttle adjusters, and hatch fasteners.

• Automotive & Aerospace – Dashboard controls, instrument panel screws, and mechanical assemblies.

• Industrial Machinery – Adjustment knobs, clamping mechanisms, and precision fasteners.

• Medical & Dental Equipment – Secure screws for ergonomic device adjustments.

Technical Specifications:

• Process: CNC turning + secondary knurling operation

• Knurling Type: CD (cross-diagonal) rolled or cut knurling

• Thread Standards: Metric, UNC, UNF, or custom threading available

• Tolerance: ±0.005" (tighter tolerances upon request)

• Finish Options: Natural, polished, anodized, or plated

Why Choose This Helm Screw?

• Superior Grip – CD knurling ensures a non-slip surface even with gloves.

• Corrosion Resistant – Ideal for harsh environments (saltwater, chemicals, high humidity).

• Custom Manufacturing – Modify dimensions, knurl pattern, or material to fit exact needs.

Request a quote for custom helm screws with specific thread sizes, knurling details, or material requirements!